Mantis Shrimp, is there anything you can’t teach us?

![Image from a webcomic [yes there is more!] by- TheOatmeal](https://loonylabs.org/wp-content/uploads/2014/04/mantis-shrimp.jpg?w=590&h=441)

Image from a webcomic [yes there is more!] by- TheOatmeal

The mantis shrimp for those of you who did not read the awesomely done comic by TheOatmeal has some of the most unique talents in the animal kingdom. Namely it’s tenacity for killing things with it’s powerful clubs.

The two arm like structures it uses move faster than a 22-caliber bullet, striking and killing it’s prey. If it misses, it moves so fast that the water around it boils and collapses on itself, also killing it’s prey. They are so vicious you won’t find them in most tanks because they will kill the other fish or break out of the glass.

The arms not only move quickly, but they are also incredibly strong, so strong labs around the world are studying the mantis shrimp for keys on how to improve body armor and other technologies.

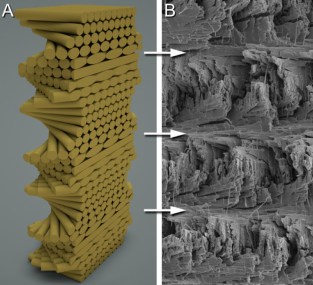

Image credit goes to: University of California – Riverside

Looking at the club structure [see above image] a team of researchers led by University of California, Riverside, in collaboration with University of Southern California and Purdue University, designed a composite that is tougher and more impact resistant than the standard used on planes.

Using the design from the mantis shrimp [again see image] the team layered carbon fiber-epoxy composites with layers that are arranged 10 to 25 degrees offset from each other [meaning the grain of the fibers were rotated 10-25 degrees from each layer looking something like this ||||| then the second layer on top would look something like this \\\\\ and so on].

They tested this design against the standard used in aerospace with a 45 degree rotation in relation to the previous layer [so 0, 45, 90, etc.] along with other designs such as the fibers all the same direction.

To test the design they dropped a spherical tip on the sheets that on impact creates 100 joules of energy. How did they stand up? The industry standard was punctured and had a ‘significant’ amount of damage. The design with a consent fiber direction completely split and failed. Lastly the design based on the mantis shrimp, while it showed signs of damage, it was not punctured.

In fact the damage from dent depth was 20 to 50 percent less than the industry standard comparison. The ultrasound showed the damage traveled laterally within the structure, rather than catastrophically rupturing through them.

Then they compressed the samples to the breaking point. Again the mantis shrimp based design faired 15 to 20 percent better than the industry standard.

“Biology has an incredible diversity of species, which can provide us new design cues and synthetic routes to the next generation of advanced materials for light-weight automobiles, aircraft and other structural applications,” said David Kisailus, a Kavli Fellow of the National Academy of Science and the Winston Chung Endowed Chair of Energy Innovation at the UC Riverside’s Bourns College of Engineering.

A key thing to note, this was simply changing the layering design, there was no added cost. Infact there was no added time over the industry standard. No new material or even a chemical binder, just pure taking a design cue from nature and applying it to something we already make. I

find these types of applications most exciting, a direct application of nature, it’s beautiful for lack of a better way of saying it.

Already a mantis shrimp and engineering master? You probably want the full study — here!

———————

Grunenfelder L.K., Suksangpanya N., Salinas C., Milliron G., Yaraghi N., Herrera S., Evans-Lutterodt K., Nutt S.R., Zavattieri P. & Kisailus D. & (2014). Bio-inspired impact-resistant composites, Acta Biomaterialia, DOI: 10.1016/j.actbio.2014.03.022

But enough about us, what about you?